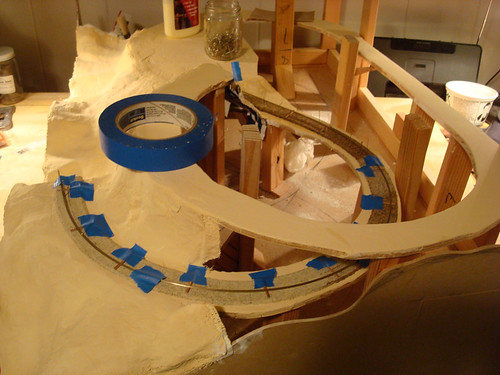

You saw the plaster coat from last time. It is now painted my base desert earth color.

Here's a closeup looking around the bend in the lower right hand side of the layout. (Side note: I should give this a name perhaps). You can see that in addition to painting the plaster coat, I've also laid down cork roadbed for the track to be layed on.

The scenic location and look that I've picked for the railroad I've narrowed down to the northern part of Arizona. Here are some shots about what I have in mind for the terrain theme for this layout:

I've been asked if there will be cactus -- Yes, there will be a little cactus here and there, but not overwhelmingly so (as in a stereotypical way).

The cork roadbed extends all the way into what will become the tunnel.

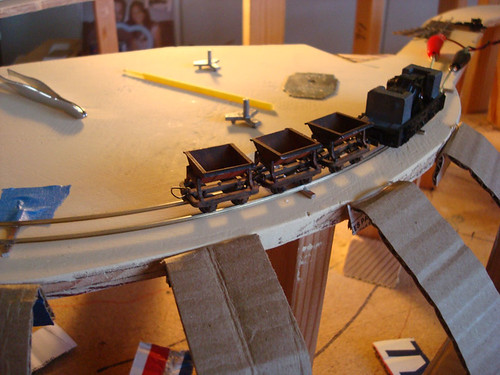

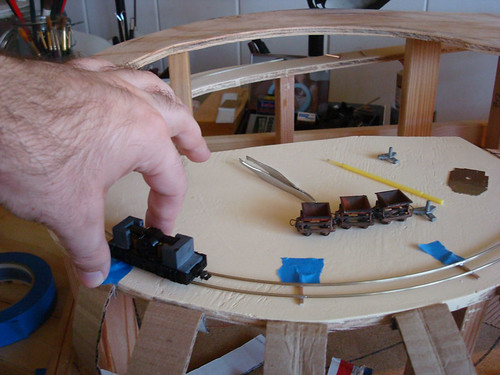

And of course how could it be a model railroad layout without track? I've begun to lay this section of track.

The track and ties are held in place with one of my favorite materials -- blue painter's masking tape (the low-tack stuff). The rails are pre-bent before installation, but are still a touch springy. In these cases I've started using pins to help them keep their shape while I work on them.

Leilani recorded a short video of how exactly the track is made, for those of you who were wondering.

Here the subtly rusted tippers sit, waiting for a train to pick them up for the next ore haul...

I've begun to build the tunnel liners as well. These will be basically cardboard, that's painted black, which will serve as the walls of the tunnel. Here they're just raw cardboard, and I'm dry fitting them to make sure the train can pass through without banging into the walls.

For this particular tunnel, I'm planning on building a wooden tunnel entrance and wooden tunnel lining, like you'd expect from a mining railroad.

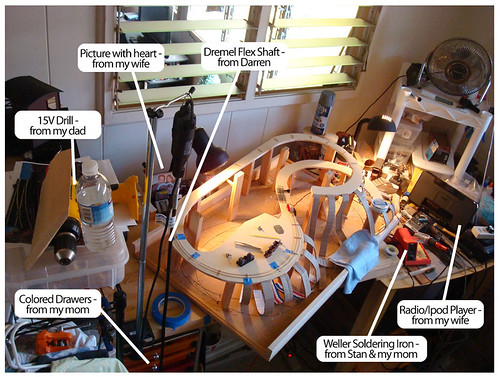

Lastly, I layed out some more roadbed, leading into the tunnel on the left, along with dry fitting some of the track.

Here's the overall progress of the layout up to this point...